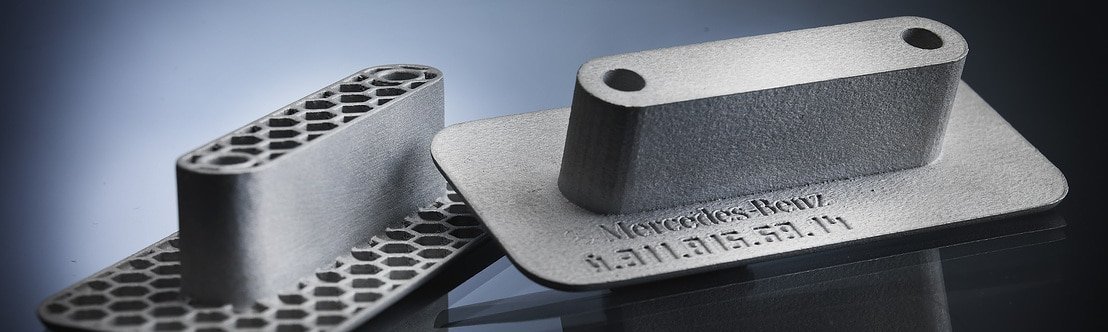

3D-printed part manufacture

For rapid, uncomplicated and efficient provision of replacement parts

Do you want special features for your Mercedes-Benz or Setra? Or do you need in-demand replacement parts that are not immediately available? Then our rapid and efficient OMNIplus 3D parts printing service offers unbeatable advantages. 3D-printed parts have the same functionality, reliability and service life as OMNIplus parts manufactured conventionally.

Just-in-time production

Currently, 40,000 bus and coach replacement parts can be printed – and the number is growing. The ultra-modern, digital component manufacturing technology of 3D printing expands and accelerates the opportunities to individualise your vehicles. Instead of lasting several months, the procurement of a 3D-printed part takes only a couple of days. What’s more: because they are stored digitally, bus and coach parts can also be produced by OMNIplus Service Points directly on site. To equip the Service Points to provide replacement parts to their customers even faster, OMNIplus has created a mobile 3D printing centre for them. This “mini-factory” in the form of a container acts here as an industrial 3D printing production centre.

High quality standards

Since 2016, Daimler Buses has set store by the possibilities of digital manufacturing using 3D printers. All 3D-printed parts are in accordance with the Daimler Truck AG quality and production standards. Parts made, say, of plastic, synthetic resin, ceramic or metal can be made to a high level of precision. Bus and coach customers benefit here from the certified, approved 3D printing quality standards and processes within Daimler Buses.

Key facts at a glance

- Long-life replacement parts of original part quality

- Rapid, flexible, cost-effective and demand-oriented parts conversion

- Ideal for low quantities

- No storage costs

- Manufacturing available on site at selected OMNIplus Service Points

- Practically no time limitation on parts availability