Daimler Buses supports bus and coach operators in achieving their objective of more sustainability without losing sight of profitability – and this also applies to the after-sales sector. Genuine Remanufactured Parts are an ecological and economical alternative to buying new parts and offer many advantages for bus and coach companies.

Cost-effective and environmentally friendly

OMNIplus offers a solution for buses and touring coaches that have been in operation for a long time and therefore demonstrate an increased need for spare parts: the remanufacturing of Mercedes-Benz and Setra bus and touring coach components at a quality matching that of new parts. "Remanufacturing" (or “reman” for short) meets high quality standards and offers impressive performance in terms of cost-effectiveness and sustainability.

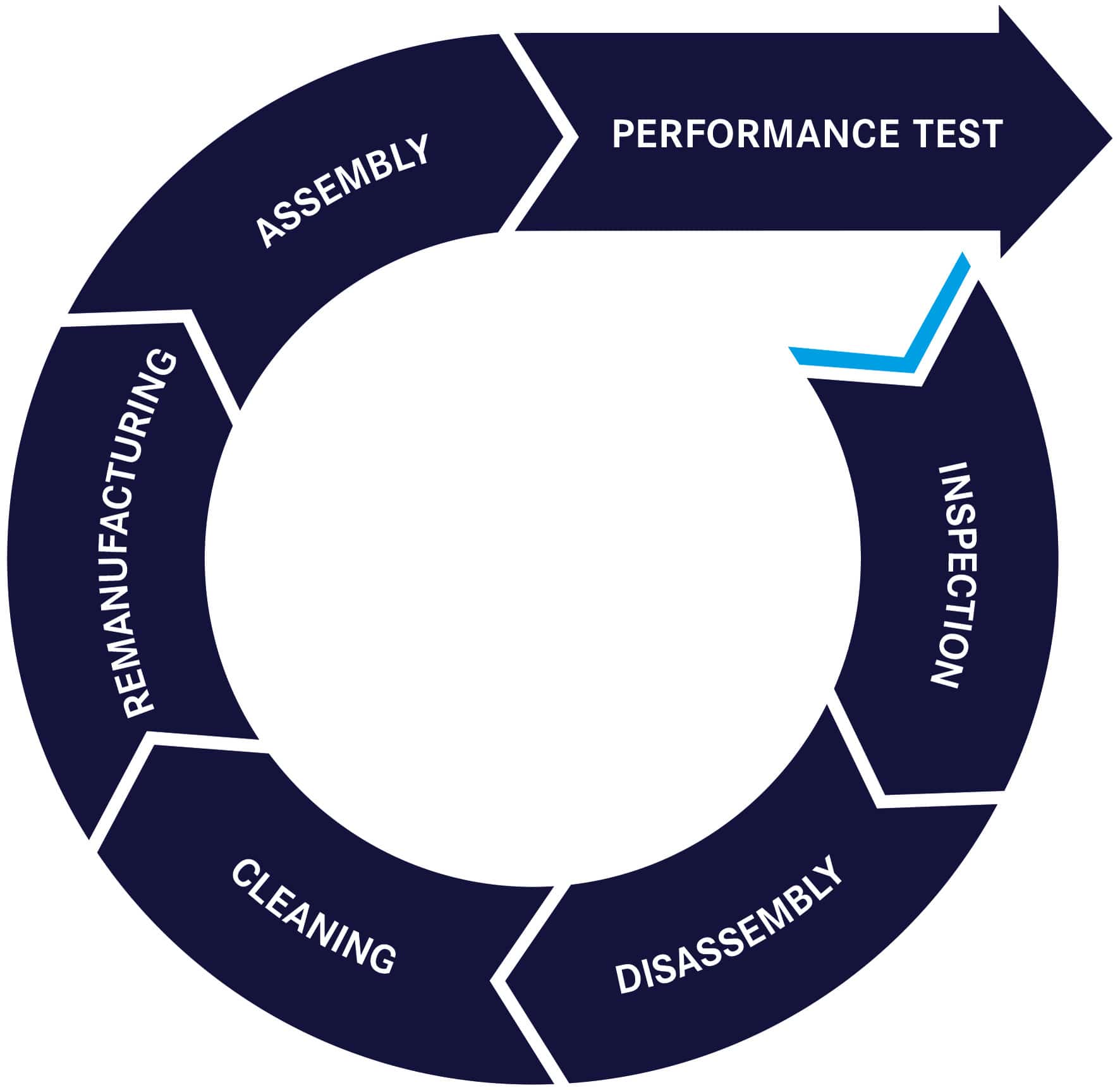

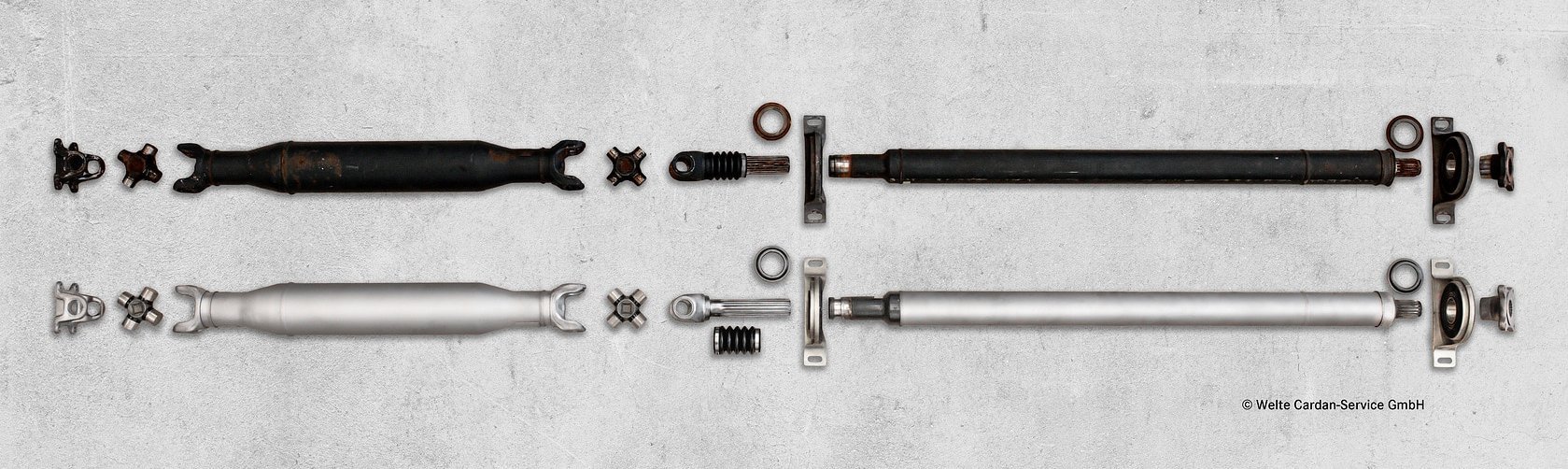

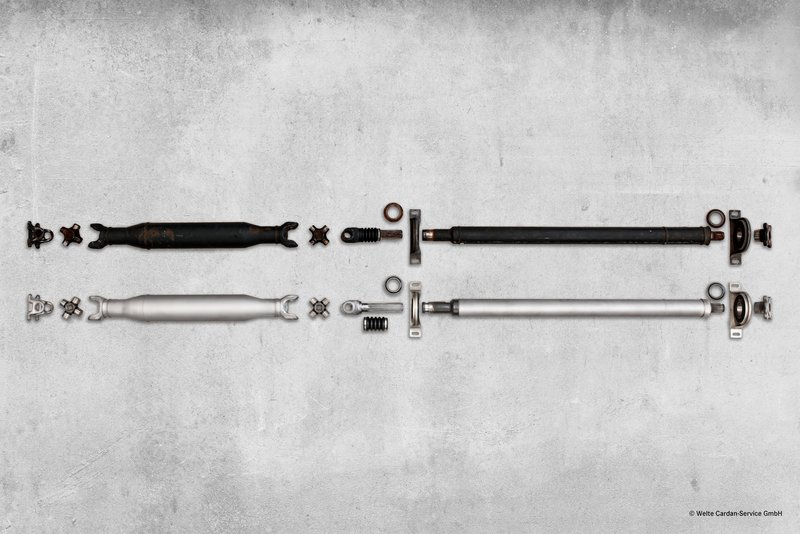

Genuine Remanufactured Parts available from OMNIplus primarily include drivetrain components such as engines, transmissions and prop shafts. In addition, the range also features parts affected by high degrees of wear, such as air compressors or alternators. OMNIplus carefully evaluates which components are suitable for reuse during the remanufacturing process. All relevant parts are disassembled, cleaned, reconditioned, assembled and put through a function test. Particularly wear-prone components and accessories are always replaced with Genuine New Parts.

Remanufacturing saves raw materials and energy. In addition to ecological aspects, such as sustainability, the preservation of resources and environmental protection, the process also reduces costs for operators compared to purchasing new parts.